What is an LFP battery? | RPM, Lithium Ferro Phosphate battery – Powertech Systems

LFP batteries

LFP abbreviation means Lithium-Fer-Phosphate (In English, lithium iron phosphate, also known under the chemical term LifePo4). These words describe the chemical composition of the battery which is different from that of an ordinary lithium-ion battery.

What is an LFP battery?

In addition to the lithium-ion batteries, a new type of batteries is quietly installed in the electric vehicle market, the LFP; But what is an LFP battery?

Although electric vehicles have demonstrated their viability in the case, manufacturers are nevertheless trying by all means to improve batteries so that they are both more efficient, more enduring, less expensive to produce and, above all, less polluting at the time of their construction while promising more autonomy to consumers.

One of the most notable advances in the evolution of batteries was the development and marketing of LFP batteries To replace lithium-ion batteries, those which currently supply the vast majority of electric vehicles on our roads.

What is an LFP battery?

LFP abbreviation means Lithium-Fer-Phosphate (In English, lithium iron phosphate, also known under the chemical term LifePo4). These words describe the chemical composition of the battery which is different from that of an ordinary lithium-ion battery.

The first attempts to use particles LifePo4 In the composition of a battery dates back to 1996. He was the engineer in chemistry Padhi and Al at the Electrochemical Society (EMS), in New Jersey, who had made this first discovery.

However, he had found that the LifePo4 particles had a very poor electrical conductivity and thus slowed down the marketing of the LFP battery. Consensus at the time had therefore been that this kind of battery could not compete with the energy density of the lithium-ion battery.

- To read: Ford will soon market LFP batteries

- To read: terminology of the electric car

It is however Michel Armand, scientist and French professor, ex-employee of Hydro-Québec, who, using his colleagues, realized that if he added carbon nanotubes to LifePo particles and reduced the size particles, we could thus compensate for the problems of conductivity.

Other researchers have also worked to develop LFP batteries, such as Yet-Ming Chiang, a chemistry engineer of Taiwanese origin. He advanced the idea of using the doping action for semiconductors, which helped increase the conductivity of an LFP battery.

What electric cars are equipped with an LFP battery?

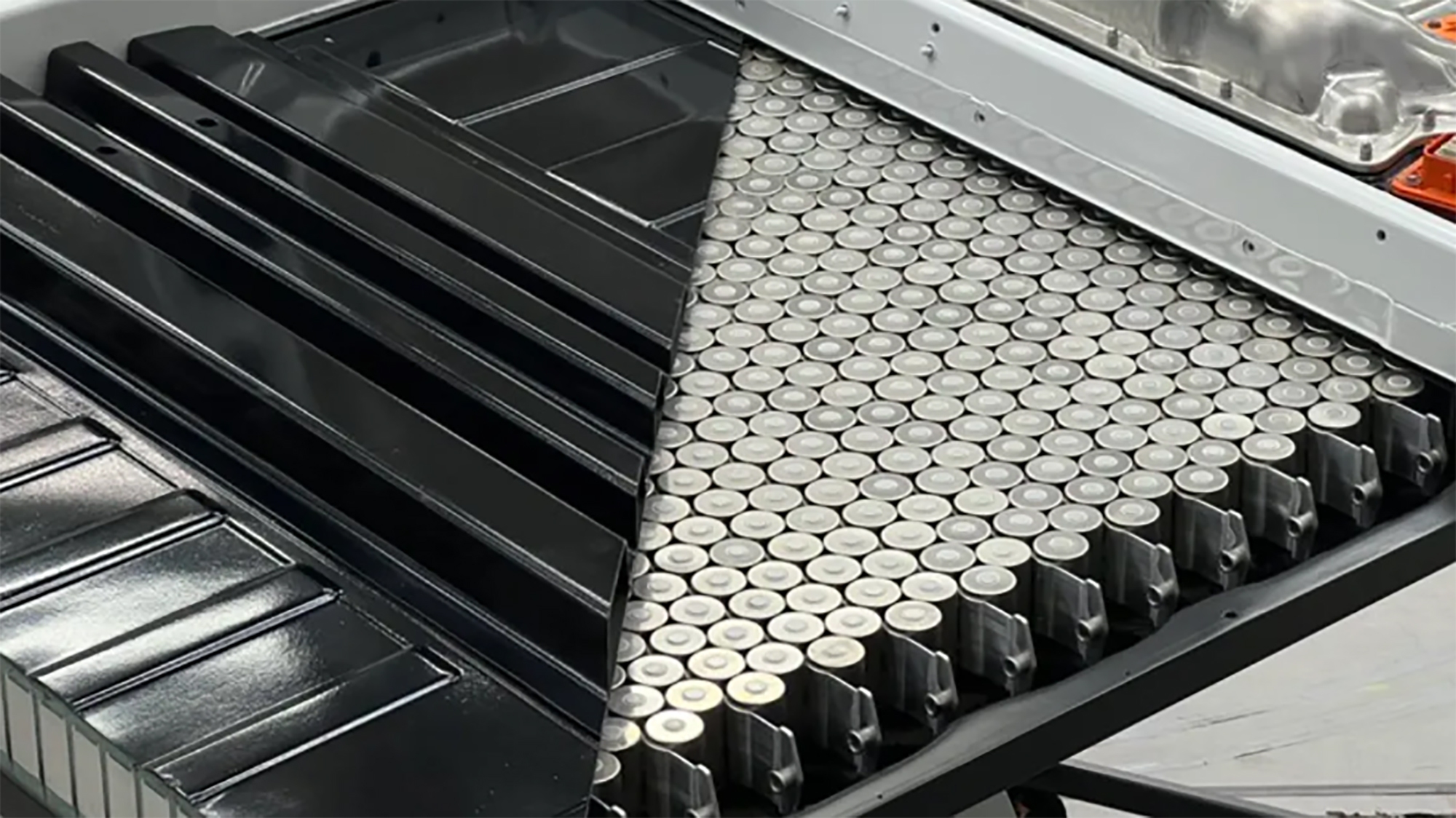

Today, due to the interest of large manufacturers in the manufacture of batteries for their lower cost electric vehicles, the LFP battery is undergoing popularity. Tesla was the first manufacturer to set it up in its Model 3 in 2021, while other manufacturers, such as Mercedes-Benz and Ford, plan to move on to this type of batteries. It was the interest of large manufacturers that has stimulated the development of this type of batteries.

How the LFP battery works with respect to the lithium-ion battery?

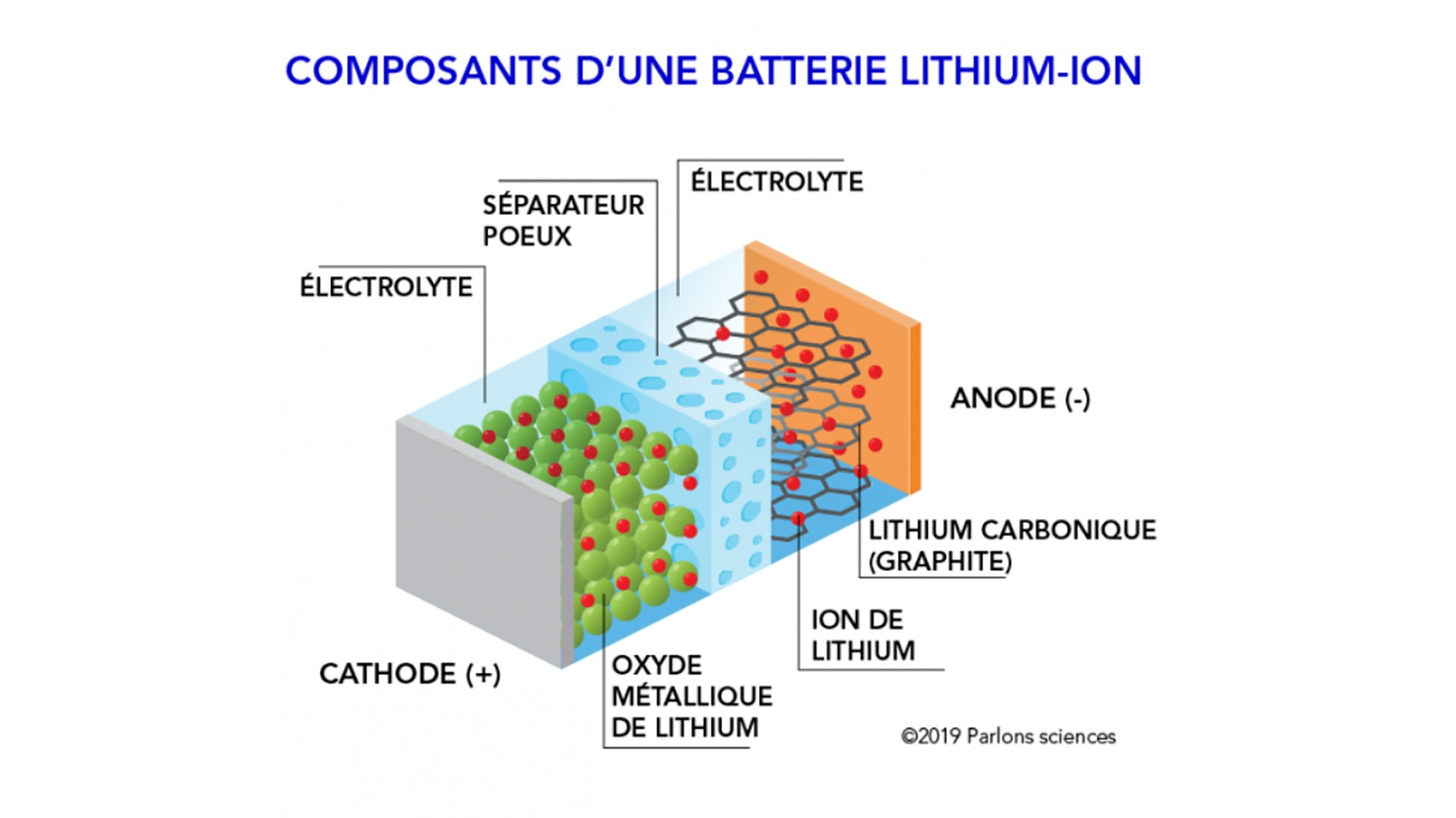

The main distinction between an LFP battery and an ordinary lithium-ion battery (NCM/Nickel-Cobalt manganese or NCA/Nickel-Cobalt aluminum) is mainly based in the chemical composition of the cathode. Instead of using metals like cobalt, nickel or manganese, we will rather prioritize iron.

It is therefore important to specify that an LFP battery also contains lithium ions inside an electrolyte. In fact, in addition to the chemical composition of the cathode, the LFP battery works exactly the same way as a lithium-ion battery. Physically, it is almost identical.

Thus, in use, it is recharged in the same way and it gives its owner the same kind of experience, with the exception of the fact that this battery can be constantly recharged at 100 % without it demonstrating Signs of premature degradation, that is to say a loss of autonomy or a slowdown in the recharge speed.

What are the advantages and disadvantages of the LFP battery?

100 % recharge is one of the main advantages of the LFP battery, because this practice does not cause premature degradation as is the case with lithium-ion battery. There is also the fact that an LFP battery is more enduring with several charging cycles. For example, if the most enduring lithium-ion batteries offer up to 1,500 charging cycles, the LFP battery can reach up to 2,000 cycles.

Then there is its chemical composition which makes it possible to reduce its dependence on controversial materials such as cobalt and nickel. Not only is the iron easier to extract and, therefore, less polluting when it is extraction, but it is also easier to recycle, which allows batteries to easily enter the existing recycling processes. There is then the cost of this metal which is clearly lower and allows manufacturers to reduce their production costs at the time of the construction of the battery.

Does the LFP battery offer more autonomy than lithium-ion battery?

On the other hand, the energy density of an LFP battery, that is to say its ability to store energy longer depending on its size (measured in wattheures/kilo), is much lower than that of batteries nickel lithium-ion. As a reference, the best lithium-ion batteries reach an energy density of 325 wattheures/kilo. The LFP battery, on the other hand, currently caps around 150 watthers/kilo.

However, this reality forces automobile manufacturers to make a battery whose capacity is higher to reach the same autonomy. The Tesla Model 3 is the perfect example. The old model had a lithium-ion battery with a capacity of 53 kilowatt hours, while the current model-equipped with an LFP battery-saw its capacity increase to 60 kilowatt hours. Finally, due to its iron-based composition, the LFP battery is much heavier than a nickel lithium-ion battery, which contributes to increasing the net mass of the vehicle.

However, recent progress in the aerodynamics of electric vehicles and energy management software, thanks to the help of artificial intelligence, in particular, allow cars to overcome these problems. As proof, despite a battery that is less energetically dense, Tesla still managed to extract more autonomy from the Model 3, which allowed her to go from 400 to 438 kilometers.

LFP batteries

Appeared in 1996, Lithium Ferro Phosphate technology (also named LFP or LifePo4) is supplanting other battery technologies due to its technical assets and its very high level of safety.

Due to its high power density, this technology is used in medium power traction applications (robotics, AGV, e-mobility, delivery of the last kilometer, etc.) or heavy traction (sea traction, industrial vehicles, etc.))

The long lifespan of the LFP and the possibility of deep cycling makes it possible to use LIFEPO4 in energy storage applications (autonomous applications, off-group systems, self-consumption with battery) or stationary storage in general.

The major assets of lithium phosphate iron:

- Extremely secure technology (no Runaway thermal phenomenon)

- Calendar lifespan> 10 years

- Number of cycles: from 2000 to several thousand (see Abaque below)

- Very low toxicity for the environment (use of iron, graphite and phosphate)

- Very good temperature resistance (up to 70 ° C)

- Very low internal resistance. Stability, even decrease during cycles.

- Constant power throughout the discharge range

- Easy recycling

Number of cycles estimated for lithium phosphate iron technology (LIFEPO4)

LFP technology is the one that allows the greatest number of load / discharge cycles. This is the reason why this technology is mainly adopted in stationary energy storage systems (self-consumption, off-Grid, UPS, help, etc.) for applications requiring a significant lifespan.

The number of real cycles that can be carried out depends on several factors:

- Lithium cell quality

- Discharge power measured in C-rate (Ex: power of 1/2 c in w = 1/2 times the capacity of the battery in Wh. For a 1kWh battery discharged at 2kW, it is said that the discharge rate is 2C)

- Discharge depth (DOD)

- Environment: temperature, humidity, etc.

The abacus below represents the number of estimated cycles for our lithium phosphate iron battery cells (LFP, LIFEPO4) as a function of the discharge power and the DOD. The test conditions are those of a laboratory (constant temperature of 25 ° C, load power and constant discharge).

In standard environment, and for cycles made at 1c, the abacus gives an estimate of the number of cycles for the LFP:

At the end of the number of cycle made, The batteries still have a nominal capacity greater than 80% of the original capacity.

- Limitations of lead batteries

- Advantages of lithium-ion

- Technical comparison Lithium-ion vs lead batteries

- Lithium-ion cost study vs lead batteries

- Lithium-ion battery safety

- Lithium Phosphate iron technology (LIFEPO4 or LFP)

- Measure the loading state (SOC) of a lithium-ion battery

The above article is the exclusive property of PowerTech Systems.

Reproduction prohibited without authorization.