Electric car battery: its composition – Izi by EDF, the battery of an electric car from A to Z

Electric car

Whatever the type of battery of your electric car, you can “extend” its lifespan by keeping it at a charge rate included Between 20 % and 80 % load. The composition of the battery of the electric models, however, implies that the battery is 100 % loaded at least once a year. This allows Battery Management System of your electric car to better understand how your battery operation.

What is the composition of an electric car battery ?

The composition of an electric car battery differs from that of a thermal car. Lithium-ons batteries are considered references in the electric automobile sector. Know what they are made up of and how these new technologies work can help you increase the life of your battery. Find out what the battery of your car is made up and optimize its life expectancy thanks to this article.

What are the components of an electric battery ?

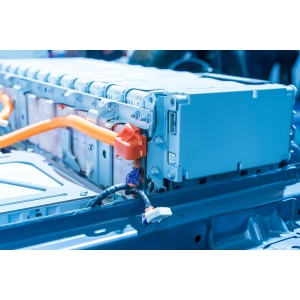

Overview of the composition of an electric car battery

The battery of your electric car is made up of electrochemical cells. They are the ones that store the energy that your electric vehicle needs to operate the engine.

Lithium, nickel, cobalt and manganese are capable of storing large amounts of energy in a compact format. This is the reason why these materials are used in the manufacture of an electric car battery.

A battery also includes a Cooling system to keep cells at optimal temperature. Other electronic components are also present. They allow you to manage and monitor the operation of your battery. The composition of an electric car battery is therefore studied for its operation, but also for a kind of “self -protection”.

What are the metals present in the batteries ?

To fully understand the composition of an electric car battery, it is interesting to know that lithium, cobalt, nickel and manganese are metals. They have very specific electrochemical properties.

Lithium is very light. It has a significant energy storage capacity per unit of weight. The same goes for cobalt, manganese and nickel. Cobalt is heavier than lithium.

Find the terminal adapted to your electric vehicle !

Wallbox Copper SB 7.4-22 KW

Product delivered and installed

See this product

Izi by EDF 7.4 kW

Product delivered and installed

See this product

Hager Witty Start 7.4 kW

Product delivered and installed

See this product

How are the batteries of your electric cars ?

To design a battery, the manufacturers must first obtain priority in raw materials such as the lithium-ion, cobalt and manganese. They then melt them and shape them into cells which are made up of each battery.

Each cell is tested to detect faults and safety before assembly of the battery. This takes place in an ultra-proper environment to avoid contamination.

This process continues until the cells form a fully functional battery, ready to be installed in an electric car. The quality insurance procedures involved in the manufacture of a lithium battery for electric car guarantee a lifespan and maximum security.

How long can an electric vehicle battery last ?

The battery life of current electric cars varies depending on several criteria:

- The number of load cycles

- The number of discharge cycles

Professionals in the automotive sector believe that an electric lithium car battery can support Between 1,000 and 1,500 load cycles. Concretely, this is equivalent to about ten years of use of your electric vehicle. This estimate is based on 15,000 to 30,000 km traveled per year.

Also note that other factors more or less directly impact the longevity and load capacity of your lithium battery:

- Its natural aging

- Its conditions of use: the type of roads on which you drive, the weather, ..

You see it, if the composition of the battery of your electric car influences its longevity, other criteria come into play.

Carburing electric has never been so Izi !

Optimize the lifespan of its lithium-9 battery: is it possible ?

The way you load your electric car will speed up or slow down the natural aging of its battery. Thus, a battery loaded or discharged too quickly will necessarily have a shorter lifespan.

These technologies are sensitive to heat. It is therefore Not recommended to make a quick recharge when it is hot. And this is especially true for an entry -level electric vehicle. For these models, the composition of the battery of the electric car has been lightened. It does not contain No cooling system, Hence the difficulty in enduring the hot weather. If you have no other choice, know that the load of your battery will be less important, or even blocked.

Whatever the type of battery of your electric car, you can “extend” its lifespan by keeping it at a charge rate included Between 20 % and 80 % load. The composition of the battery of the electric models, however, implies that the battery is 100 % loaded at least once a year. This allows Battery Management System of your electric car to better understand how your battery operation.

Why does the power of a lithium battery become less efficient over the loads ?

The very composition of an electric car battery plays on lithium battery performance. This type of battery suffers from the Solidification of lithium ions. After a number of charges and discharges, the ions provide less energy.

This type of technologies requires that the battery be active regularly. A bit like a thermal car.

If your electric car has stayed for a while without rolling, we advise you to ask for advice from professionals before loading it again. This type of battery does not appreciate that the ions will solidify, and this is precisely what is happening in the event of inactivity.

You now know the composition of an electric car battery. Electric models remain a still quite recent technology. It is therefore a safe bet that manufacturers will find a way to further optimize the operation and lifespan of an electric battery.

On your side, if you have abandoned your thermal car for an electric car, you may be interested in the electric motor in order to fully understand all the components of your new car.

Electric car

Make all the light on the battery of the electric vehicle

Reading time: 6 min 5

The principle of the battery is more than a century old, but it has revolutionized our time. Today many electronic appliances operate on battery, including phones and laptop who have radically upset the communications. Increasingly efficient, the traction battery, Reserved for transport, now shakes up the parking ! Without it, there would be no electric or hybrid vehicles and green mobility would always be a utopia. Its operation is unknown, its recycling is controversial, not a day without being talked about, zoom in on the battery !

Anatomy of an electric battery

Schematically, a battery is an energy tank, an accumulator made up of a heap of small cells which each contain a anode (negative electrode), a cathode (positive electrode), a separator and a electrolyte.

This strata stack transforms chemical energy into electrical energy during discharge and electrical energy into chemical energy during loads.

In a accumulator, The electric current enters and fates through the anodes and cathodes that change their role depending on if the device loads or discharge.

THE electrons circulate in a conductive liquid called electrolyte where the electrochemical reaction is formed, initially resulting from a couple lead/acid.

In terms of technology, the battery has evolved well since its invention in the 1860s, but the basic principle remains the same.

There battery power varies according to the number, size and assembly of cells. THE electric cars batteries (traction battery) are different from those that equip thermal vehicles. On the latter, the battery gives the power necessary for start -ups, but is not efficient enough to supply an electric motor.

The automotive industry has therefore tested other electrochemical couples in order to obtain accumulators that combine power and lightness in a low volume and at the best cost:

- Nickel/Cadmium (Ni-CD)

- Nickel/Metal Hydride (Ni-MH)

- Nickel/Zinc (Nizn)

- Nickel sodium/chloride (Zebra)

- Sodium

- Lithium/ion (li-ion)

- Lithium/polymer (lipo)

- Lithium/phosphate (LifePo4)

- Lithium/polymer metal (LMP)

It is to this day the battery lithium-ion best results.

The power of a traction battery

In electricity, the measurement units are the watt, the volt and the ampère.

The Watt corresponds to the electrical power. It is obtained by multiplying the volts by the amps.

The volt gives the electric voltage while the ampere gives the intensity.

The storage capacity of a traction battery, a real car’s energy tank, is expressed in kWh.

It varies according to the car model from 50 to more than 100 kWh.

Lithium-ion battery

Present in 95 % of current batteries, lithium meets the needs of different technologies of electrified vehicles: hybrids, Rechargeable hybrids, with fuel cells and 100 % electric.

There lithium-ion battery contains various elements, metals and minerals, among which we can cite copper, manganese, aluminum, graphite, nickel, sometimes cobalt And of course, lithium.

It presents all the qualities required in terms of:

- energy density, which is the energy it contains expressed in volume or unit of weight,

- load speed, expressed in unit of time,

- lifetime, time in which performance is annoyed.

Lifespan of an electric battery

This is expressed in Recharge cycles, that is to say in number of charges and discharges complete. The lifespan of a lithium-ion battery is 1,000 to 1,500 charging cycles, from 8 to 15 years, depending on the use of the vehicle.

Some good practices allow it to be preserved as much as possible.

It is recommended in particular to stay at a load level between 20 and 80 %, to favor Loading time short as well as slow charges to limit any overheated.

THE fast charges in roads or electric station must remain occasional.

Moreover, it is better to avoid deep discharges and long periods without rolling.

A battery loses approximately 2 % performance (autonomy, power and speed of load) each year. This capacity is measurable in a mechanic thanks to State of Health, Or Soh at the score expressed in percentage.

What is the price of a battery ?

It represents about 40 % of the car price, ie 8,000 to more than € 20,000 depending on the model.

To lower the invoice, some manufacturers offer it by rental for a monthly cost between 70 and 150 euros.

Each of these solutions has advantages and disadvantages, to be studied on a case -by -case basis.

At the top in any season

Despite technological progress, it hardly appreciates extreme temperatures linked to the heat wave or the frost of winter !

The ideal is to park the car under a shelter or better, in a garage.

In winter, It is recommended to start the car to heat it while it is still connected to the electrical network so that it does not impact the charge too much.

However, don’t worry, because the new car models are equipped with heat pumps, much less greedy than electrical resistors.

In the heart of the electric car

THE electrification system hybrid is different from that of an all -electric.

In some cases, the battery offers vehicle assistance, in others, it is the centerpiece.

We are going to be particularly interested in the latter, because it will be the only diagram after 2035, the date on which thermal vehicles will no longer be produced.

Operation of a traction battery

The clean car has one or more electric motors. These generally operate with alternating current and are powered by the battery that stores direct current.

The electricity journey between the different parts is ensured by a power electronics which ensures the transformation of the current during the load or discharge of the vehicle and during braking.

There battery charge is done via a connection on one of the different types of charging stations.

This energy passes through a on -board charger, Or converter. This transforms the alternating current into direct current stored in the traction battery.

The engine is controlled by a electronic management case called chopper (engines fed by direct current) or inverter (engines fed by alternating current).

Power electronics regulate recharging, controlling the air conditioning compressor and heating.

The engine (s) then leads (nt) the wheels.

The battery also stores the energy released by the deceleration induced during braking phases.

Regenerative braking

The engine of Hybrid and electric cars is consumer, but also energy producer thanks to the braking system.

Whoever equips thermal vehicles was revised and corrected so that the energy released during the braking and deceleration of the vehicle, called kinetic energy, are no longer lost.

It is recovered and then transformed by the various electronic components before being stored in turn in the traction battery.

The energy thus recovered allows a decrease in consumption of the order of 7 to 12 %, especially in urban cycles.

Note that this adaptation always offers the comfort and efficiency of Emergency braking and braking assistance.

The recycling

Because of the time or the vagaries of the road, apart from the fact that the operation can quickly be expensive, A battery changes ! Depending on the age of the vehicle, it can then be wise to opt for the rental.

But what about used battery ? According to a European directive, the producer of the battery is in theory responsible for its recycling. This obligation aims to avoid abandonment in the great outdoors of Very polluting chemical components.

This mission is most often entrusted to specialized and approved organizations.

It is then dismantled, because almost all of its components keep a commercial value.

The percentage of recycling imposed by law is 50 %, but in fact, it is much higher, around 75 %.

THE Metals and materials are recovered during various operations.

Anything that cannot be re -used is treated according to a recycling process well defined.

However, if it no longer has enough power for a car, it can still have enough capacity to serve as stationary storage, alone or sets in series.

Detractors of Park electrification only have to be right, the batteries are entitled to a second life and are not as dangerous as it is said !

Gest’europe puts all its expertise at the service of automotive professionals with tailor -made support, especially in electromobility.

- Electric and cold vehicle: what should be known before winter ?

- Lithium batteries

- Electric vehicles

- Connected battery

- VE/VH power electronics

- Regenerative braking